When machines like CNC waterjet cutters work specifically on food stuff items for cutting, Some others are used for packing or creating cooking equipment. Some widespread applications are:

As we move in to the 2030s, mass production will more and more trust in advanced CNC machines Outfitted with AI and machine Discovering.

Commence-up charges can be diminished by lowering the volume of element rotations or repositioning required to finish the section, for example, separating geometries into several parts that may be assembled later on.

You will find a variety of machines and equipment for precision machining as a result of vast applications of the process. A variety of parts have to have differing types of cutting, so A selection of cutting tools happen to be formulated.

CNC has never been additional vital, with numerous nations building their Concepts For brand new ammunition and defense systems. Every one of these Strategies are brought to existence with the precision machining process, which employs various materials and strategies.

Pc-aided style generates a computerized graphical representation of your section. This representation is simple to be aware of for designers, operators, and producers. Nonetheless, the CNC machines that make the section do indirectly grasp this electronic format.

CNC machining does not have to generally be used independently of Yet another manufacturing course of action. Combining it with other processes like 3D printing or metal casting may result in superior parts and merchandise.

Although precision machining may be necessary for sure functions and dimensions, it may be a big squander of methods to need precision machining when normal machining tolerances would suffice.

Our sound high quality-control process is sensible that 1000s of customers location their CNC machining orders inside our firm. The typical check and testing commences from incoming materials to shipment, guaranteeing Every component is manufactured accurately for your requirements.

Firstly, excellent precision machining demands a superior-conclude cutting tool capable of taking away the material carefully to match the desired product dimensions.

The Taiwanese agency effectively includes a “Russian domestic sales” branch that provides use of a wide array of corporations in Moscow’s military services industrial complex, they wrote.

CNC milling is really a machining system that works click here by using computerized controls and rotating multi-position cutting tools to remove material from the workpiece and develop a custom-developed portion or product. This process is appropriate for machining a range of materials, which includes metal, plastic, glass, and Wooden, as well as developing various custom-developed parts and products and solutions.

The workpiece is stationary in Pc Numerical Manage drill presses, while a rotating drill little bit rotates close to and drills holes in the workpiece.

Computer system Aided Manufacturing (CAM) computer software works by using two different types of codes – the G and M codes. The G code controls the coordinates of the cutting tool. The M code controls the auxiliary functions from the machine, which include turning the coolant flow on or off.

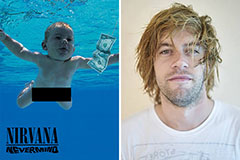

Spencer Elden Then & Now!

Spencer Elden Then & Now! Brian Bonsall Then & Now!

Brian Bonsall Then & Now! Robbie Rist Then & Now!

Robbie Rist Then & Now! Kane Then & Now!

Kane Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now!